PTFE hose which was initially used in hydraulic or pneumatic systems or in the aerospace sector is rapidly becoming popular. Hoses and tubes made out of PTFE perform brilliantly, under challenging environmental and industrial conditions, and hence its commercial usage across industries is on the rise. Due to its high commercial usability and its exceptional properties, PTFE products are an important commodity of the industrial, medical and consumer markets, where they are used not only in the traditional way but also in non-traditional and unconventional ones.

What is a PTFE lined hose

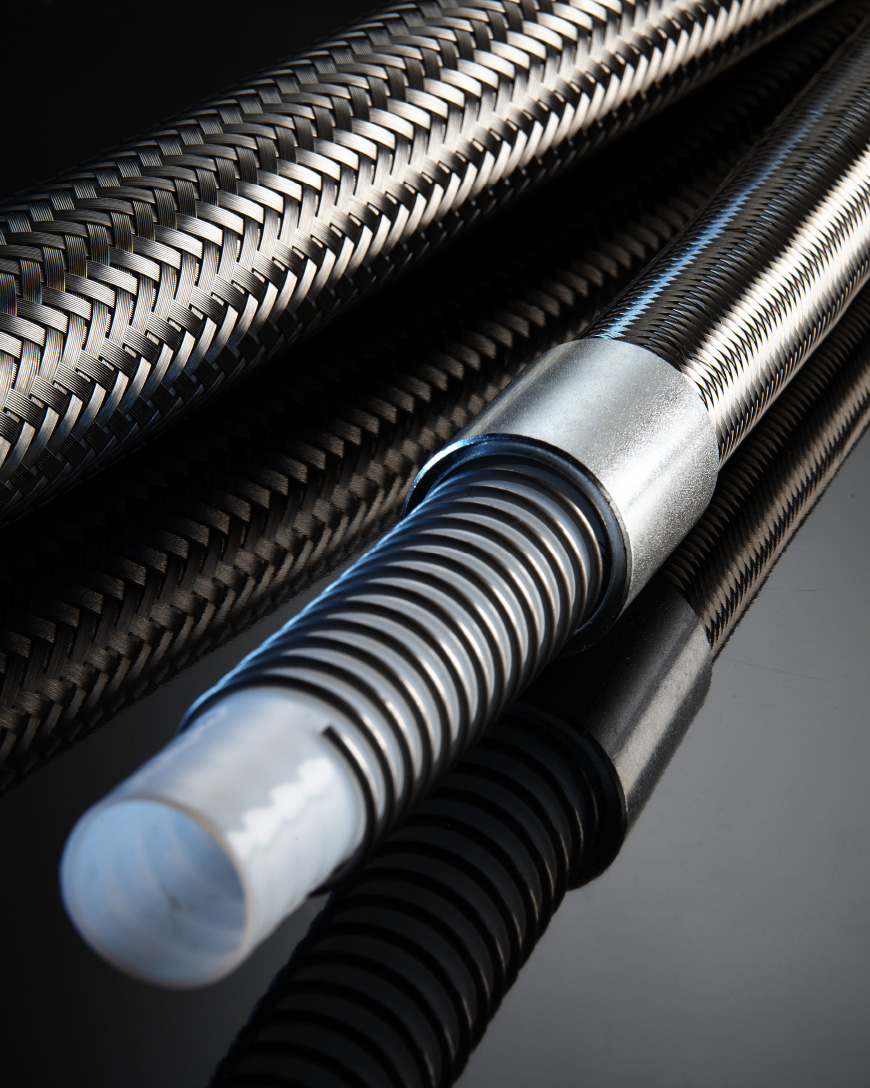

PTFE Hose is a tube consisting of an inner PTFE liner and an outer protective cover. The PTFE liner is similar to a PTFE tube having an outer protective cover which increases its pressure withstanding capacity. The combination of outer cover and inner PTFE liner makes a hose an important instrument in many applications.

Characteristics of PTFE tubing

PTFE tubing possesses the following characteristics:

- Resistance to heat and cold

- Resistance to corrosion

- Absence of toxins and high purity

- Exceptionally low permeability

- Resistance to fatigue

- Light Weight

- Convenience of sanitizing and cleaning

- Resistant to Ultraviolet rays and ozone

- Chemically inert

- Resistance to water

- Shock Resistance

- Anti-static

Classification of PTFE tubing

The following features need to be considered for PTFE tubing, when selecting them for a particular application.

- Convoluted or smooth bore: The main distinguishing factor in case of a PTFE hose is the bend radius and the size. The bore size for a smooth bore will be either less than, or equal to one inch. Also, the bend radius of a smooth hose will be a minimum of 12 inches while that of a convoluted bore will be a minimum of 3 inches.

- Non-conductive or conductive: Static charges are those charges, which get generated by some medium when the charges flow through the PTFE hose tubes at high velocities. These static charges if neglected, can lead to a dangerous situations like explosions. As a result of this, PTFE hoses are sometimes manufactured with special materials which are anti-static, which avoid static charge buildup

- Thickness of the PTFE hose wall: PTFE braided hose are manufactured with different thicknesses of their walls. In applications where severe flexing of the hose takes place, thicker walls are preferred as they provide a better resistance to buckling. The thick walls of a hose also provide a lower permeability for gases, but they occupy more space.

- Braid Material: Type 304 stainless steel braid is usually the material of choice in most cases. However, in case of marine applications, type 316 stainless steel braid is used. Besides, the braid used should be made up of stainless steel if the hose is to be used in an extremely corrosive environment. And, the braid should be made up of bronze, in case the hose is going to be used in a high frictional environment, due to its good lubricating property.

Application of PTFE tubing

- Oil and Gas Refineries

- Steel Plants

- Power Plants

- Paper Mills

- Pharmaceutical Industries

- Fertilizer Industries

- Chemical Industries

- Industrial Boilers

- Air Conditioning and refrigeration

- Nuclear Installations

- Automotive Industries

- Ports and Shipyards

+91 7028773123

contact@aftubes.com